Electron Backscatter Diffraction (EBSD) Analytical Service

- Orientation Mapping: Determination of crystal orientation across the scanned area.

- Grain Size and Distribution: Measurement of grain size and identification of grain boundaries.

- Grain Boundary Characterization: Classification of boundaries (e.g., high-angle vs. low-angle, Σ-values).

- Crystallographic Texture: Mapping the statistical orientation distribution of grains.

- Phase Identification: Differentiation between crystalline phases within the sample.

- Strain and Distortion Analysis: Using Kernel Average Misorientation (KAM) to evaluate local strain and lattice distortion.

Electron Backscatter Diffraction (EBSD) Analytical Service is a crystallographic structural analysis technique performed on a scanning electron microscope (SEM) platform. By conducting area scans, EBSD enables the reconstruction of two-dimensional and even three-dimensional crystallographic maps, providing visual and quantitative data on a material's microstructure.

In fields such as materials science, metallurgy, geology, and functional ceramics, understanding the relationship between microstructure and performance is essential for research and engineering optimization. Crystallographic parameters—including grain size, crystal orientation, texture distribution, and grain boundary characteristics—directly influence mechanical strength, corrosion resistance, electrical conductivity, and workability. Traditional optical microscopy and X-ray diffraction (XRD) methods are limited in spatial resolution and localized structural analysis, making it difficult to obtain quantitative crystallographic information at the micro- to sub-micron scale.

Electron Backscatter Diffraction (EBSD) is a high-resolution technique for analyzing crystal orientations, integrated into SEM systems. It enables visual and quantitative characterization of surface crystal structures, grain boundaries, texture features, and microstrain under high spatial resolution conditions. EBSD is an essential tool for studying recrystallization behavior, phase transformation mechanisms, twinning structures, and material anisotropy.

MtoZ Biolabs offers Electron Backscatter Diffraction (EBSD) Analytical Service to analyze crystal orientation, grain size, grain boundary features, texture distribution, and phase structure at the micro- and submicron scale. Our service provides high-quality crystallographic data to support research into material mechanisms, performance prediction, and process optimization.

Technical Principles

Jackson M A. et al. Integr Mater Manuf Innov. 2014.

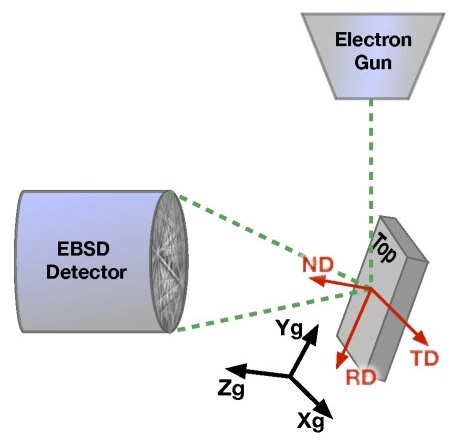

EBSD is based on the crystallographic diffraction behavior of high-angle backscattered electrons within a scanning electron microscope (SEM). When an incident electron beam strikes a polished sample surface at a tilted angle, some electrons penetrate the sample and are diffracted by the crystal lattice planes in specific geometric directions. These interactions form distinctive diffraction patterns—known as Kikuchi patterns—on a phosphor screen or detector. The geometry of these patterns is directly related to the crystal orientation of the sample.

By analyzing these patterns, the system can calculate the crystal orientation at each scanned point and perform the following analyses:

With EBSD’s 2D and 3D mapping capabilities, it is possible to achieve quantitative and visualized characterization of the evolution of crystallographic structures in materials.

Analysis Workflow

Electron Backscatter Diffraction (EBSD) Analytical Service at MtoZ Biolabs includes the following key steps:

1. Sample Preparation

Samples are mechanically polished to a mirror finish. If needed, further polishing is performed using electrolytic or ion beam methods to ensure the high surface quality required for electron diffraction.

2. Mounting and Positioning

The sample is mounted in the SEM at a typical tilt angle of 70° to optimize the collection of backscattered electron diffraction signals.

3. Area Selection and Parameter Configuration

The region of interest is selected, and scanning parameters are defined, including step size, accelerating voltage (typically 15–30 kV), and detector settings.

4. Kikuchi Pattern Acquisition

At each pixel, a Kikuchi diffraction pattern is captured and matched against a crystallographic database to extract orientation data.

5. Image and Data Generation

Grain orientation maps (IPF), grain boundary maps, texture maps, and misorientation maps (e.g., KAM) are generated, along with key data such as grain size, orientation distribution, and interfacial characteristics.

6. Result Analysis and Reporting

A complete technical report is delivered, containing raw data, orientation statistics, grain boundary characterizations, and quantitative texture analysis.

Applications

Electron Backscatter Diffraction (EBSD) Analytical Service is suitable for microstructural studies and engineering evaluations across a variety of materials. Typical application areas include:

Microstructural Analysis of Metallic Materials

Statistical evaluation of grain size and distribution for assessing heat treatments such as annealing, recrystallization, and rolling.

Analysis of twins and high-angle grain boundaries in relation to mechanical properties.

Identification of grain orientation effects on corrosion behavior or crack initiation mechanisms.

Ceramics and Functional Coatings

Study of phase structure and polycrystalline texture.

Evaluation of coating–substrate interface bonding, thermal barrier stability, and residual stress accumulation.

Investigation of grain boundary migration and phase transformation during in-situ sintering processes.

Geological and Mineral Materials

Precise identification of mineral phases and crystallographic relationships in multiphase regions.

Analysis of microstructural evolution and recrystallization mechanisms in strained zones.

Micro-scale reconstruction of natural processes such as weathering, metamorphism, and tectonic deformation.

Biomaterials and Bioinspired Structures

Crystallographic orientation and mechanical correlation in bone tissue and enamel.

Optimization of grain alignment in biomimetic mineralized materials.

Interface control in nanocomposites across multiple length scales.

FAQ

Q. How can I determine whether my sample surface quality is sufficient for EBSD analysis?

Surface quality can be assessed based on pattern clarity, indexing rate, and noise level under SEM. Clear Kikuchi patterns and an indexing rate above 80% generally indicate adequate sample preparation.

Q. How does EBSD distinguish between different phases in multiphase samples? Is a custom crystallographic database required?

EBSD identifies phases by matching Kikuchi patterns to standard unit cells in the crystallographic database. For common phases (e.g., FCC, BCC, HCP), built-in databases typically suffice. However, for complex, metastable, or rare mineral phases, users must import custom crystallographic data (e.g., space group, lattice parameters, symmetry operations) to ensure accurate pattern matching. The reliability of phase identification depends on pattern quality, accelerating voltage, and indexing tolerance. It is recommended to verify known phases beforehand and use EDS data for complementary elemental confirmation.

Case Study

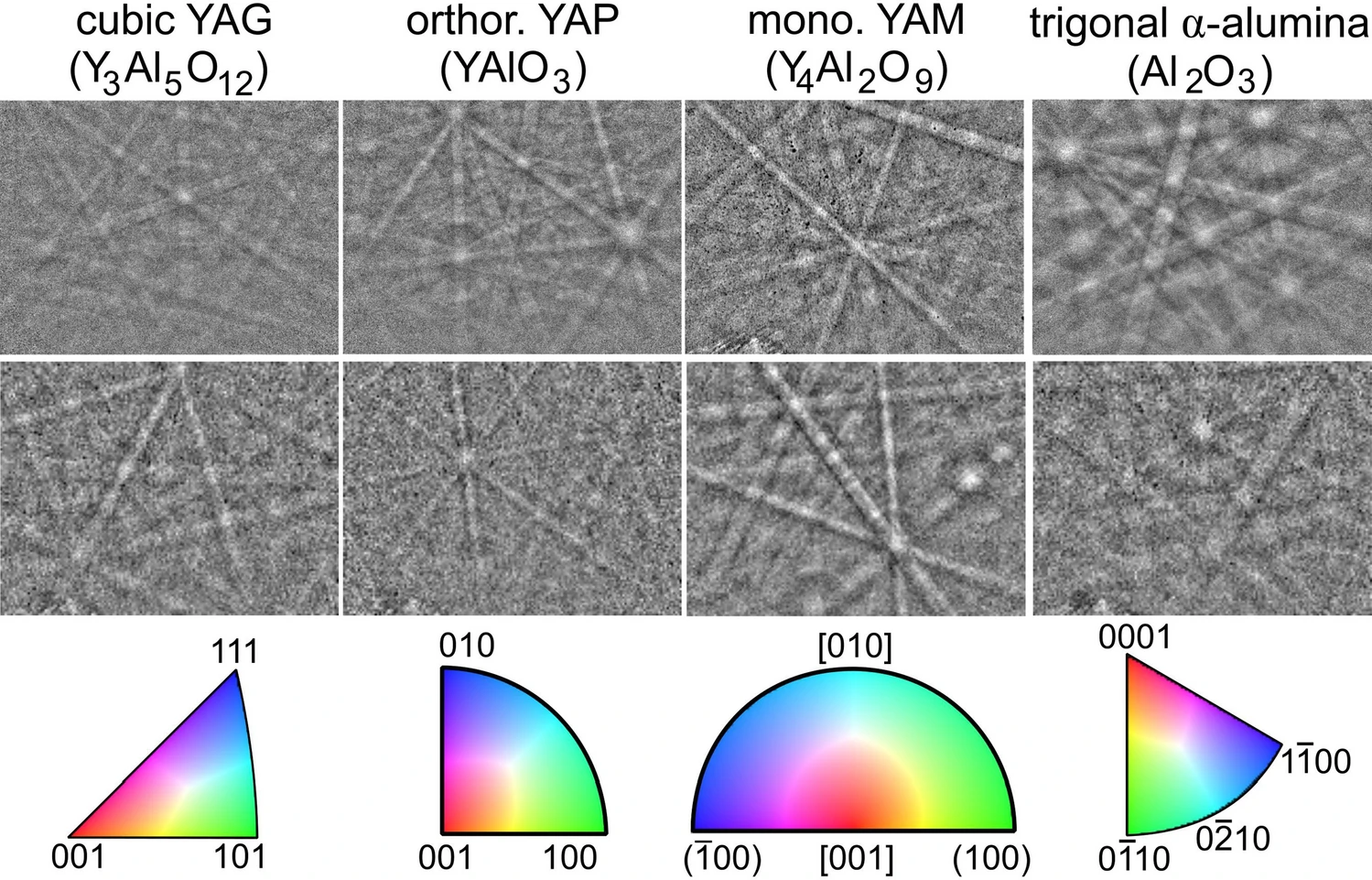

This study employed EBSD to analyze the crystallographic structure and crystallization behavior of Y₂O₃–Al₂O₃ microspheres synthesized via flame synthesis. EBSD results revealed the formation of multiple crystalline phases under different heat treatment conditions, including YAG (Y₃Al₅O₁₂), YAP (YAlO₃), YAM (Y₄Al₂O₉), and α-Al₂O₃, each exhibiting distinct grain morphologies and orientation characteristics. The EBSD maps also revealed inhomogeneous crystal growth and multiphase coexistence, reflecting the microstructural evolution mechanisms driven by rapid cooling and complex phase transformations.

Wisniewski W. et al. Sci Rep. 2020.

How to order?