In-situ X-ray Diffraction (XRD) Analytical Service

In-situ X-ray diffraction (XRD) analytical is a technique used to monitor real-time changes in the crystal structure of materials under specific environmental conditions (such as temperature, atmosphere, or applied voltage). Its basic principle involves irradiating the sample with X-rays and recording the shifts in diffraction peaks corresponding to various interplanar spacings based on Bragg’s law, thereby enabling the analysis of structural evolution behaviors such as phase transitions, stress release, and crystallization/amorphization processes. Unlike conventional XRD, in-situ XRD can capture dynamic structural information under actual material states, featuring high temporal resolution and non-destructive characteristics.

In-situ X-ray diffraction (XRD) analytical service is widely applied in multiple fields, including energy materials (such as lithium-ion battery electrodes, fuel cells, and thermoelectric materials), catalyst structure stability studies, high-temperature behavior analysis of metals/ceramics, monitoring of crystal phase transformation processes, and control of thin film deposition. It is particularly suitable for studying structural responses of materials under thermal treatment, atmospheric modulation, or electrochemical stimulation, providing crucial support for new material development, reaction mechanism elucidation, and process optimization.

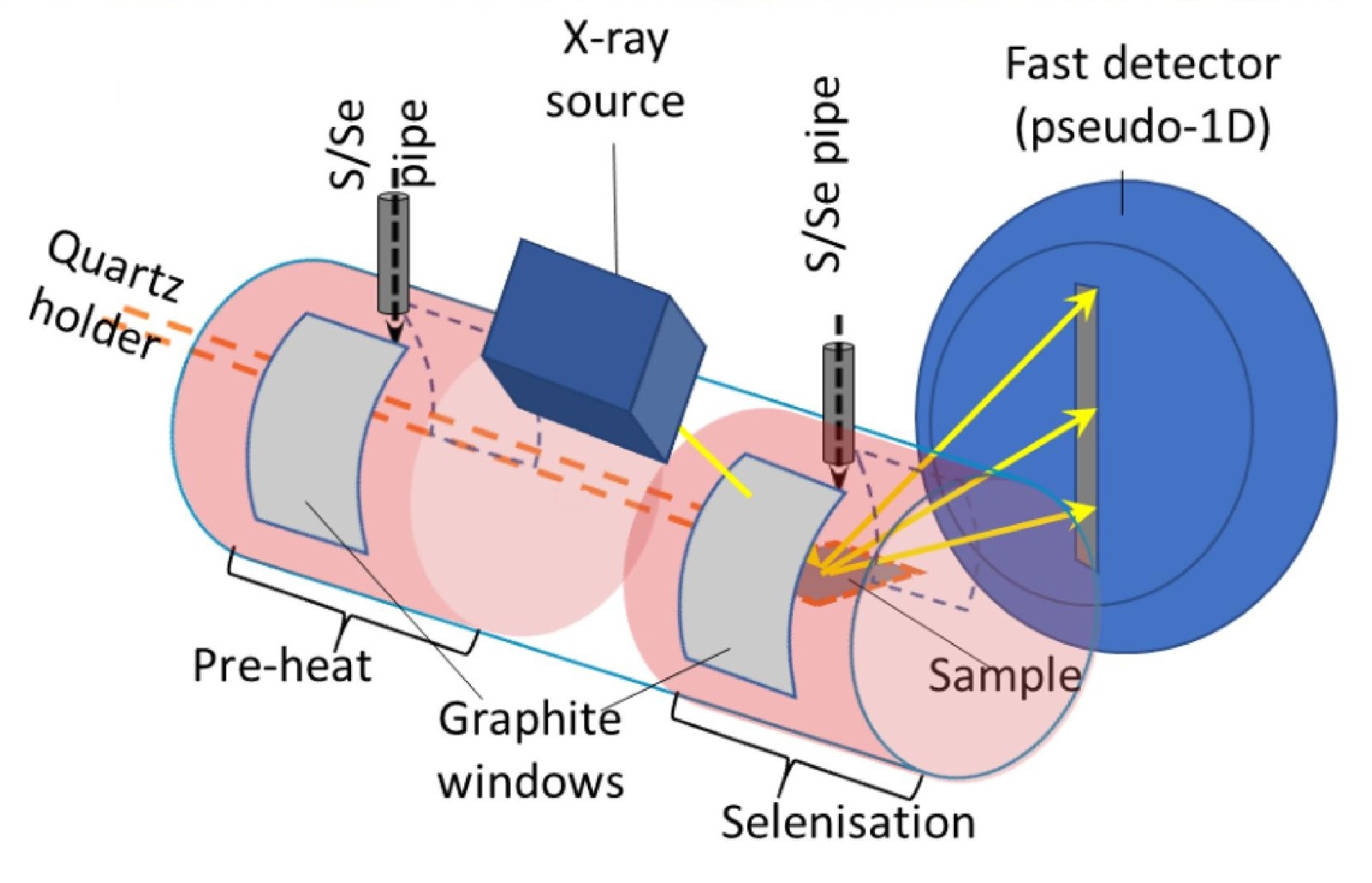

Aninat, R. et al. Solar Energy, 2021.

Figure 1. Schematic Summarising the Principle of the In-situ XRD Measurement.

Services at MtoZ Biolabs

Based on a high-resolution in-situ X-ray diffraction platform, MtoZ Biolabs provides in-situ X-ray diffraction (XRD) analytical service for real-time monitoring of crystal structure evolution under actual working conditions, such as heating, reducing, or oxidizing atmospheres. This service accurately captures key data including phase transitions, lattice parameter changes, and crystallization behavior at various reaction stages. The results offer high temporal resolution, strong repeatability, and structural reliability, making the service ideal for structural regulation studies and material performance optimization.

Analysis Workflow

1. Sample Preparation and Mounting

The material under investigation is processed into a form suitable for XRD analysis and mounted into an in-situ sample cell equipped with temperature control, atmosphere regulation, or electrochemical environment adjustment, ensuring sample stability and consistency in data acquisition.

2. In-Situ Condition Setup

Experimental conditions such as heating rate, atmosphere type (e.g., air, nitrogen, hydrogen), pressure, or applied bias are configured according to research objectives to simulate real service or reaction environments.

3. XRD Data Acquisition

During the reaction or treatment process, X-ray diffraction spectra are continuously collected to record dynamic changes in the crystal structure, including phase transitions, stress–strain behavior, and lattice parameter evolution.

4. Data Analysis and Structural Characterization

The collected XRD spectra are processed for peak fitting, phase identification, crystallinity analysis, grain size estimation, and stress evaluation to elucidate the structural evolution of the material under in-situ conditions.

5. Results Delivery and Technical Support

A comprehensive report is provided, including experimental conditions, dynamic diffraction patterns, structural evolution trends, and technical recommendations, supporting scientific publication, process evaluation, or material screening.

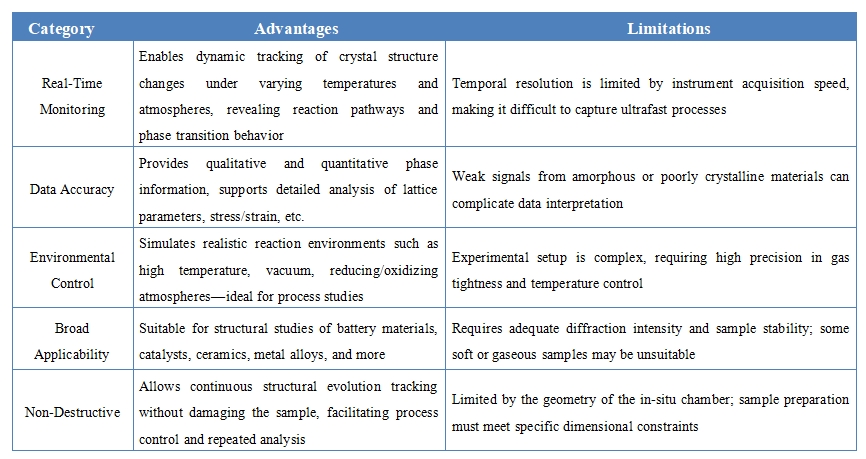

Advantages and Limitations

Applications

1. Phase Transition Behavior Analysis

In-situ X-ray diffraction (XRD) analytical service enables real-time monitoring of phase transitions in materials subjected to heating, pressure, or atmospheric changes. It is suitable for analyzing thermal treatment behavior in metal oxides, alloys, ceramics, and other materials.

2. Structural Evolution of Battery Materials

By observing lattice changes in electrode materials (e.g., lithium-ion or sodium-ion batteries) during charging and discharging, this service helps elucidate energy storage mechanisms and structural stability.

3. Catalyst Operating State Monitoring

In-situ X-ray diffraction (XRD) analytical service can be used to analyze the evolution of active phases and crystallization behavior of catalysts under reaction atmospheres and elevated temperatures, supporting mechanistic studies and performance optimization.

4. Atmospheric Response and Stability Evaluation

By tracking the structural response of materials under various gas environments (e.g., H₂, O₂, CO₂), this service evaluates environmental stability and operational adaptability.

5. Stress and Strain Analysis of Materials

In-situ X-ray diffraction (XRD) analytical service is applicable to studying stress-induced phase transitions or lattice distortions in composite or structural materials during mechanical loading, aiding in the assessment of mechanical performance and failure mechanisms.

Case Study

1. In-situ XRD Study of the Effects of Amino Acids on the Carbonation Kinetics of Cementitious Calcium Silicates

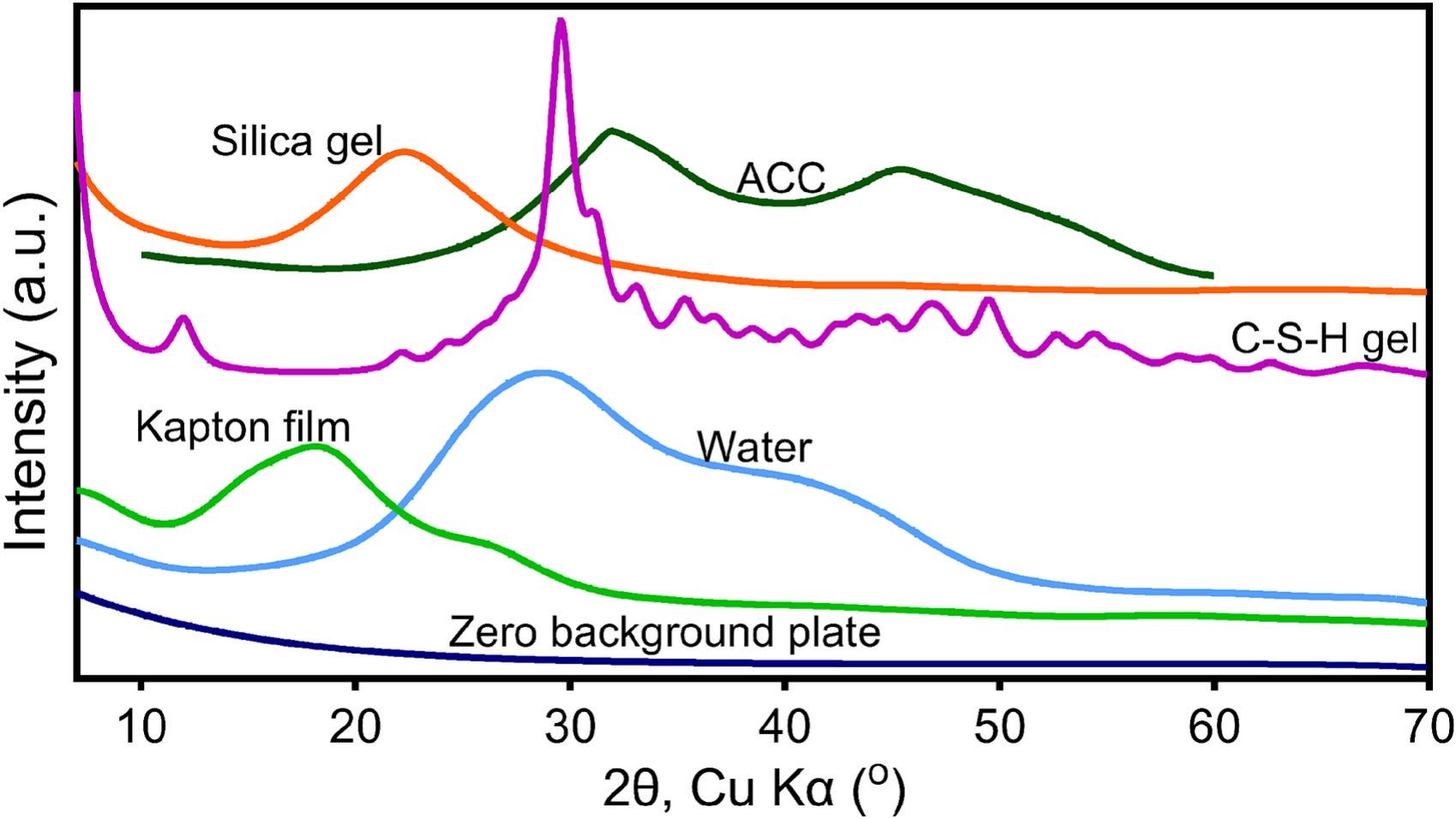

The study aims to investigate the effects of amino acids on the carbonation kinetics of cementitious calcium silicates using in-situ X-ray diffraction (XRD) technology. The research targets include calcium silicate hydrate (C-S-H) and white Portland cement clinker. Under controlled CO₂ concentration and temperature-humidity conditions, the study compares the carbonation behavior of samples with various amino acids (such as glutamic acid, glycine, and lysine) to that of control samples without additives. In-situ XRD was employed to monitor in real time the formation rate and phase transition of calcium carbonate polymorphs. The results demonstrate that different amino acids significantly influence the carbonation rate and the transformation pathway of calcium carbonate phases (vaterite, calcite), with lysine notably delaying the carbonation process. The study concludes that amino acids, as organic modulators, can affect the mineral phase transitions and kinetics of carbonation reactions, offering a new strategy for improving the carbon capture efficiency and durability of cement-based materials.

Chen, Z Y. et al. Cement and Concrete Research, 2025.

Figure 2. XRD Patterns for Selected Amorphous Components.

FAQ

Q1: What Is the Difference between In-situ XRD and Conventional XRD?

A1: Conventional XRD is limited to analyzing the crystal structure of static samples, whereas in-situ XRD enables real-time monitoring of structural evolution under conditions such as heating, atmosphere control, or electrochemical loading, making it suitable for studying dynamic reaction processes.

Q2: Is Customized Experimental Design Supported?

A2: Yes. MtoZ Biolabs offers tailored experimental setups, including adjustable heating rates, atmosphere types, and time-resolved measurement schedules, to meet the specific needs of both research and industrial applications.

How to order?