Biopharmaceutical Product-Related Impurities Analysis Service

During the production of bioproducts, it's common to find impurities not only produced in the manufacturing process but also related to the desired products. These product-related impurities typically consist of product variants that do not align functionally with the target product. The most common variants arise from chemical modifications, as well as from the degradation and aggregation of the target product. Protein heterogeneity are often caused by various unexpected post-translational modifications (PTMs), such as deamidation, acetylation, and improper disulfide bond formation. Techniques such as peptide mass fingerprinting, chromatography, and electrophoresis can be employed to detect these variants. Additionally, size-exclusion chromatography (SEC) is used to identify variants from the degradation and aggregation of the target product.

Product-Related Impurities

1. Degradation Products

Antibodies or proteins may degrade during production and storage, resulting in fragments or modifications such as oxidation and deamidation. These require detection using techniques such as mass spectrometry (MS), high-performance liquid chromatography (HPLC), and capillary electrophoresis (CE).

2. Polymers and Aggregates

Dimers, trimers, and other polymer forms need to be analyzed using SEC, HPLC, and MS.

3. Variants

Including isoforms and glycosylation variants, which are analyzed using techniques like MS, isoelectric focusing (IEF), and CE.

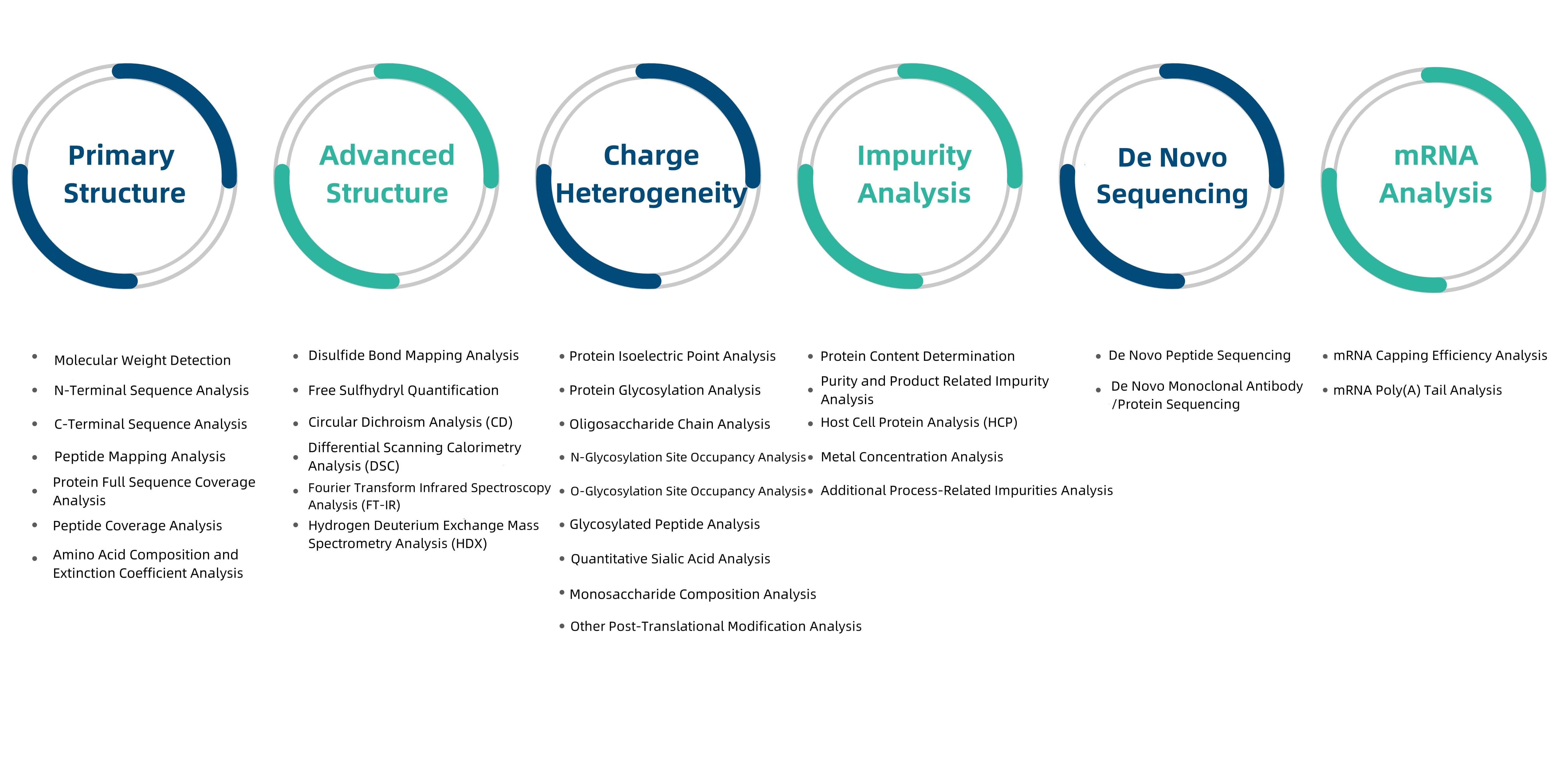

MtoZ Biolabs employs an array of sophisticated analytical techniques, such as high-resolution MS, MALDI TOF, high-performance chromatography, and capillary electrophoresis (CE), to analyze product-related impurities in bioproducts efficiently and accurately. Additionally, MtoZ Biolabs offers further characterization services for bioproducts.

Services at MtoZ Biolabs

Deliverables

1. Experimental Procedures

2. Instrument Parameters

3. Raw Data

4. Analysis Results of Product-related Impurities in Bioproducts

How to order?